ERATZ Engineering

VeraMASS

A brief introduction to VeraMASS

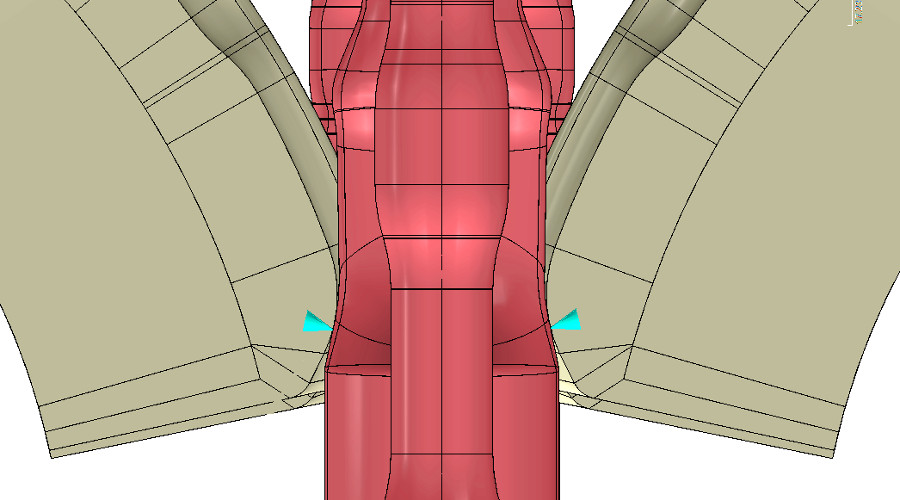

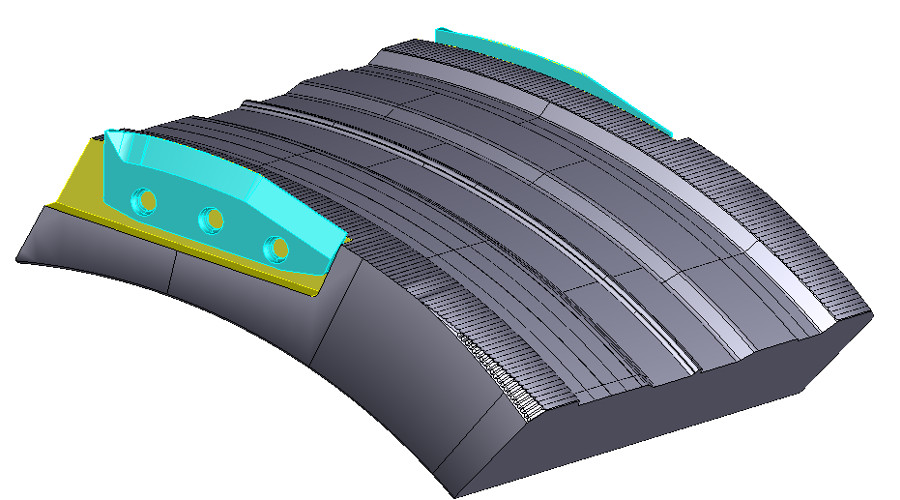

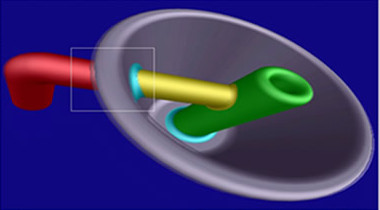

VeraMASS refers to the forging industry and is used to develop mass distribution diagrams and stage plans for closed-die forging processes. The aim is to save material and energy with a mass distribution adapted to the end product, and on the other hand to design a process stable stage plan that minimizes tool costs. A good stage plan design is characterized by the fact that the material is not excessively deformed. Otherwise there is a heavy load on the tool with high wear. A good stage design also relies on minimal use of materials in order to minimize costs and the CO2 footprint of the product. The material flow simulation using FEM is an excellent tool today to make these relationships visible as early as the construction phase, but it requires a few loops to get correct the mass distribution. To simplify the design process, a new program from the Vera software family from the ERATZ engineering office is now being launched: VeraMASS.This program reads in the formats STEP, IGES, STL, VDAFS and Euklid Native and automatically creates the material distribution along the blank axis or along the center-line of a component (skeleton line) made from a curved forging part. The program is available for long forgings, but also contains functions for vertical or rotationally symmetrical forgings. VeraMASS is an easy to use program for importing and visualizing complex 3D geometries. A special feature of the visualization are different techniques for the visualization of technological values on the component surface (isolines). The forging process chosen is independent of the development of the tool stages.

VeraMASS is suitable for the target procedures:

- Reducer Rolling

- Cross Wedge Rollin

- Form Rolling

- Upsetting

Downloads

Download the latest version of VeraMASS here.VeraMASS + VeraCAD as complete installation package.

Software

More

Imprint

ERATZ EngineeringHerrmann Eratz

Kirchhörder Str. 94

44229 Dortmund

Germany

Phone +49 (0)231 72 73 290

Fax +49 (0)231 72 73 291

E-Mail: he@eratz.de

© 2023 ERATZ Ingenieurbuero